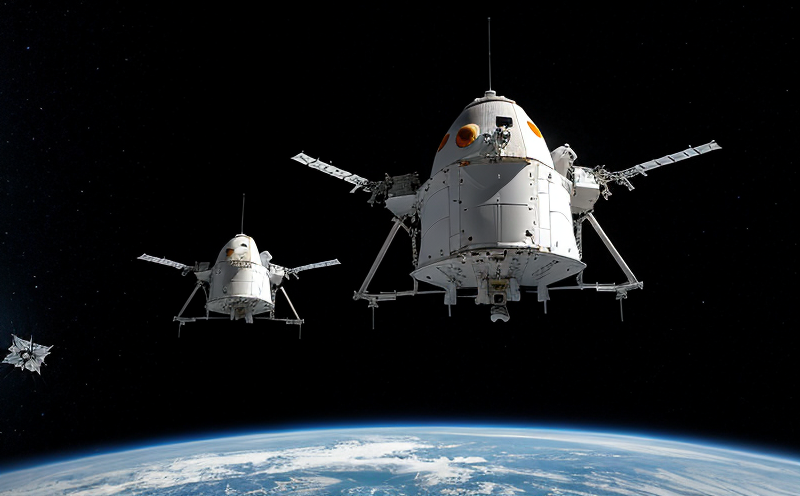

Spacecraft Testing and Design: The Crucial Path to Space Exploration

As space agencies and private companies continue to push the boundaries of space exploration, the importance of spacecraft testing and design has never been more critical. A well-designed and thoroughly tested spacecraft is essential for ensuring the safety of both the crew and the mission objectives. In this article, we will delve into the intricacies of spacecraft testing and design, highlighting the key factors that make a successful mission.

Designing the Spacecraft: Key Considerations

The design of a spacecraft involves considering various factors, including mission requirements, crew safety, and performance specifications. Some of the key considerations in spacecraft design include:

Mission Objectives: The primary objective of the mission will determine the type of spacecraft needed. For example, a deep space probe requires different characteristics than a satellite designed for Earth orbit.

Crew Safety: Spacecraft must be designed to ensure the safety and well-being of the crew. This includes provisions for life support systems, emergency power sources, and adequate living quarters.

Performance Specifications: The spacecrafts performance specifications will depend on its intended mission. For example, a high-speed probe requires advanced propulsion systems, while a communications satellite needs reliable communication equipment.

Testing the Spacecraft: A Step-by-Step Process

Once the design of the spacecraft is complete, it undergoes rigorous testing to ensure that it meets all the required specifications. The testing process involves several stages:

Static Testing: This stage involves simulating various conditions, such as launch vibrations and extreme temperatures, to test the spacecrafts structural integrity.

Dynamic Testing: In this stage, the spacecraft is subjected to simulated flight conditions, including high-speed motion and turbulence.

Environmental Testing: The spacecraft is exposed to extreme environments, including temperature fluctuations, humidity, and radiation exposure.

In-Depth Analysis of Spacecraft Design and Testing:

Here are two detailed paragraphs in bullet point format providing additional information on the design and testing of spacecraft:

Spacecraft Materials and Structures:

Spacecraft materials must be lightweight yet strong to withstand the harsh conditions of space.

Composites, such as carbon fiber and Kevlar, are commonly used due to their high strength-to-weight ratio.

The structure of the spacecraft is designed to provide adequate support for the crew and equipment while minimizing weight.

Propulsion Systems:

Spacecraft propulsion systems can be categorized into three main types: chemical rockets, ion engines, and solar sails.

Chemical rockets are the most common type used in launch vehicles but have limitations in terms of efficiency and specific impulse.

Ion engines offer higher efficiency and longer mission times but require more complex systems.

QA Section

1.

What is the primary difference between spacecraft design for deep space missions versus Earth orbit?

The primary difference lies in the propulsion system, with deep space probes requiring high-efficiency engines to achieve escape velocity from Earths gravitational pull.

2.

How do spacecraft designers ensure that the crew has a safe and comfortable living environment?

Designers consider factors such as life support systems, emergency power sources, adequate lighting, and temperature control to provide a safe and habitable environment for the crew.

3.

What is the significance of environmental testing in spacecraft design?

Environmental testing simulates the harsh conditions that spacecraft will encounter during launch, transit, and operation in space, ensuring that the spacecraft can withstand extreme temperatures, radiation exposure, and other factors that could compromise its performance or safety.

4.

Can you explain the concept of static versus dynamic testing?

Static testing involves simulating various conditions to test a spacecrafts structural integrity, while dynamic testing subjects the spacecraft to simulated flight conditions, such as high-speed motion and turbulence.

5.

How do spacecraft designers account for the effects of radiation on electronic components?

Designers use specialized shielding materials and designs to minimize exposure to radiation and prevent damage to sensitive electronic equipment.

6.

What is the role of computer simulations in spacecraft design and testing?

Computer simulations, such as finite element analysis (FEA) and computational fluid dynamics (CFD), help designers predict and optimize spacecraft performance under various conditions without the need for physical prototypes.

Conclusion

Spacecraft testing and design are crucial components of any space mission. A well-designed spacecraft ensures that crew safety is not compromised, while thorough testing guarantees that the spacecraft can withstand the harsh conditions it will encounter in space. By considering key factors such as mission objectives, crew safety, and performance specifications, designers create a reliable and efficient spacecraft capable of achieving its intended mission goals.

Additional Resources

For those interested in learning more about spacecraft design and testing, the following resources are available:

NASAs Space Technology Mission Directorate (STMD) provides information on spacecraft technology development and testing.

The European Space Agency (ESA) publishes detailed reports on spacecraft design and testing for various missions.

Online courses and training programs offer comprehensive instruction on spacecraft systems, propulsion, and materials.

By understanding the intricacies of spacecraft design and testing, we can better appreciate the complexity and challenges involved in sending humans to space.